Continuous tempersture measuring probes | Protectuve tube(MZ Tube)| Expendable thermocouple |

Japan Thermotec co.,Ltd. that contributes to manufacturing such as steel making,cast metal foundry, and conner base alloys making.

Site Search >>

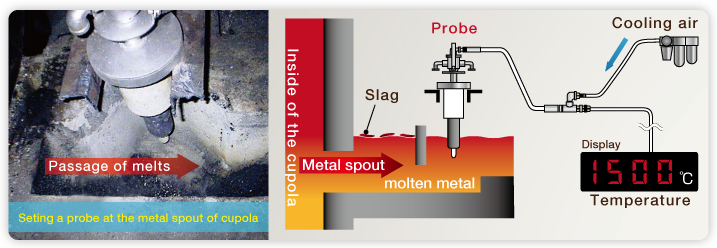

The temperature of the molten metal in the steel maker (tundish), in the foundry (cupola, holding furnace, and automatic pouring machine), and in the copper base alloy foundry (melting furnace and holding furnace) are continuously measured.

- There is a best proven track record, the best measuring time was for 300 hours or more, at the tundish (1,500℃ ~ 1,590℃) in the steel maker.

- There are proven track records, measuring time was for from 10 days to 30 days, at the metal spout of the cupola in the foundry.

- There are proven track records, measuring time was for six months or more., at the melting furnace / the holding furnace in the foundry of copper base alloy.

We are contributing in various method such as quality of product, energy conservation, stability operation, and worker's reduction of burden.

※The development product actually used is published on the actual results and the usage pages.

-

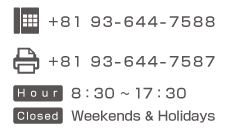

Basic structure

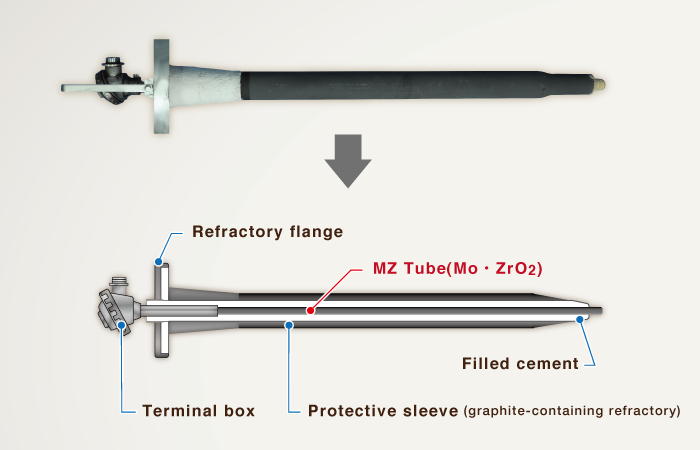

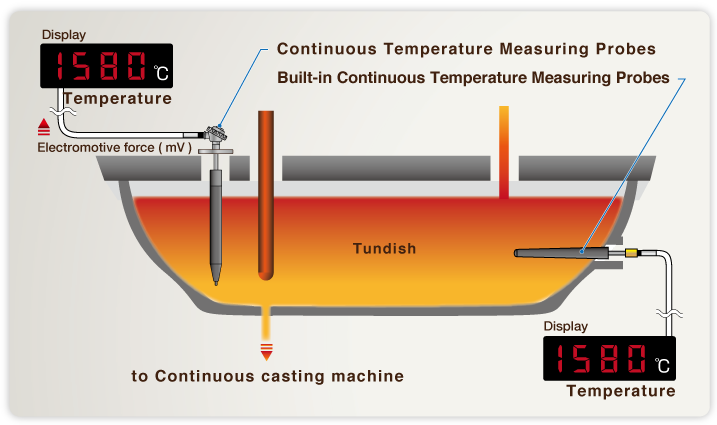

Example of equipment outline when using it in the tundish

Component profile

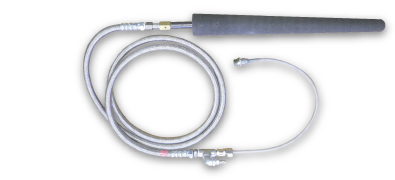

MZ Tube (Mo-ZrO2) It is a cermet protective tube to make from Mo and ZrO2 of high melting point , excels in strength at high temperature and in thermal shock resistance, and has high corrosion resistance for the molten steel and slag, etc. Protective sleeve It is a protective tube to make from graphite-containing refractory to protect MZ tube from oxidizing, is used as a countermeasure against dissolved loss (improvement of the service life of the probe) with molten steel and slag, also excels in thermal shock resistance( From room temperature to 1500℃) Platinum thermocouple There are two choices, type R thermocouple (Pt-Rh13%/ Pt) and type B thermocouple (Pt-Rh30%/ Pt). Type B is mainly recommended because R thermocouple is more deterioration due to use in the high temperature region. Temperature measuring probe will be designed about size of the main body, the terminal box, and the compensating leadwire, and the metal connectors(with quick connect coupling for air cooling) and the flanges, etc. in order to be well adapted for the molten metal, equipment, and usage. These design will be matched to each customer and produced. Please feel free to contact us if you have any questions or comments.

Specification data

Whole specification

Items Specification Weight of probe 3 〜 12 kg Shape of probe Ø50〜90 / Ø25 × 300 〜 1,000 Measuring range MAX 1,700℃ Response time About 2 minutes 30 seconds

(from room temperature to 1570℃)Connection method of probe Connector method

(metal connector, one-touch connector)Protective Tube (Thermo-Alloy)

Items Characteristic value Material Mo-ZrO2 Density 8.3g / cm3 Bending strength 342MPa Thermal conductivity 68.1W / (m・k) Thermal expansion coefficient 7.2 × 10-6 / ℃ Resistance to thermal shock It is possible to dip it with no preheating into molten steel. Protective Sleeve (Refractory)

Items Characteristic value Material AI2O3(Alumina) - Carbon, Others Apparent porosity 14.9 % Bulk specific gravity 2.60 Bending strength 9.4 Mpa Elastic modulus 10.3 Gpa Thermal expansion coefficient 5,2 × 10-6 / ℃ Resistance to thermal shock It is possible to dip it with no preheating into molten steel. Structure of Continuous Temperature Measuring Probes - END -

-

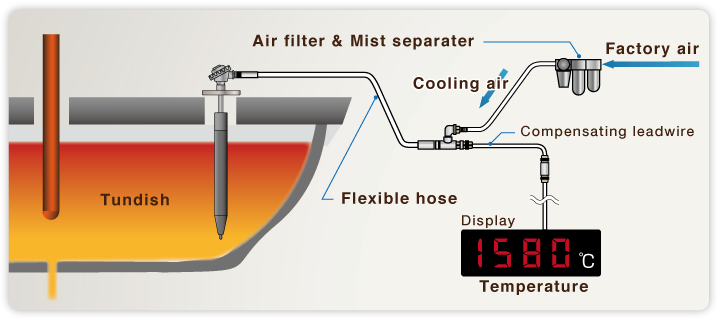

JT probe-S for tundish of steel maker

Standard type probe

※This is one example. Various types are publish on the actual results and the usage pages.

Probe for plasma heating device

※This is one example. Various types are publish on the actual results and the usage pages.

Profile MZ tube that has excellent corrosion resistance and thermal shock resistance as the thermocouple protective tube is adopted. Graphite-containing refractory is adopted to protect from the dissolved loss on the slag line part of the cermet. It is possible to use it without the preheating in the high temperature area of 1500℃ or more. Anti-corrosion and anti-spalling characteristics of the probe is improved by applying the special coating agents on it. The response to the temperature change is quick. Steel process at which Continuous Temperature Measuring Probes is used

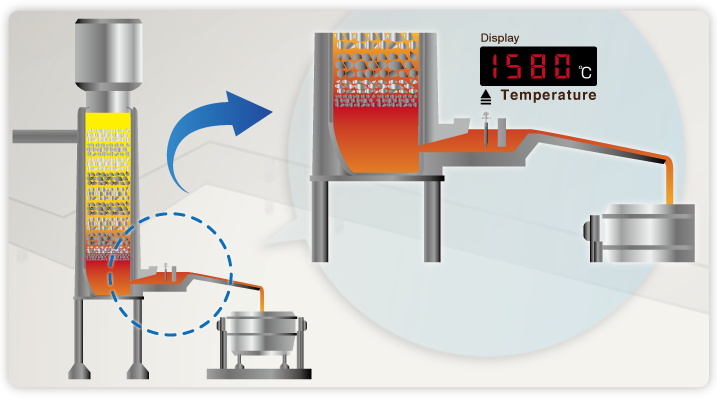

It is used at the continuous casting that is the final process of the steel refining. This process is to solidify molten steel to specific size solid.

Outline of continuous temperature measurement

Because continuous casting is final process of the refinement, temperature of molten steel in tundish is important parameter in order to influence the quality of product and the operating condition. Continuous Temperature Measuring Probes can continuously measure this temperature for a long term. ※ Use in the ladle is also possible.

Explanation by illustration One example of the product usage Stationary type probe

※One example. Various types are publish on the actual results and the usage pages.

Wall mounted type probe

※One example. Various types are publish on the actual results and the usage pages.

Large temperature display

※One example. Various types are publish on the Expendable thermocouple page.

Use at tundish of probe - END -

-

Continuous Temperature Measuring Probes for cupola (castiron) - Grey Iron

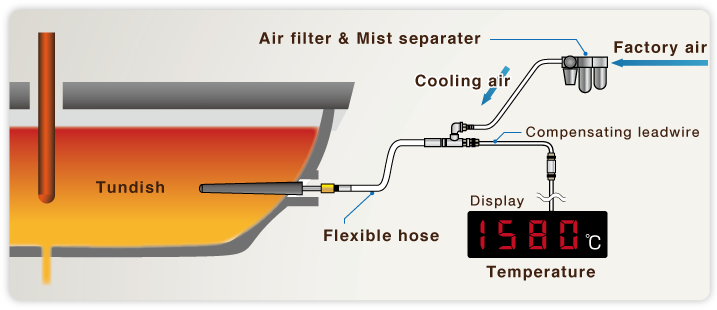

There are proven track records, measuring time was for 10 days (over 200 hours), the environment was from about 1500 degrees Celsius to about 1530 degrees Celsius.It is possible to measure the temperature with high accuracy, using an exclusive flexible hose (cooling air method).The probe which uses Thermo-Alloy for cast iron is used to control the temperature at the metal spout of the cupola.

Explanation by illustration One example of the product usage Probe

※One example. Various types are publish on the actual results and the usage pages.

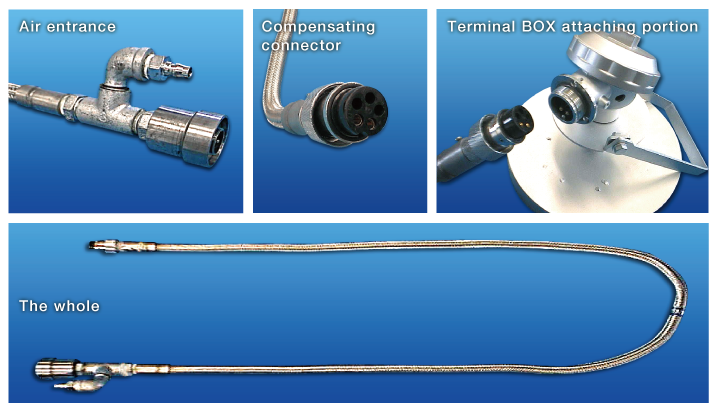

Feature of flexible hose

The temperature in the compensating contact becomes constant at low temperature by cooling the connector area of Continuous Temperature Measuring Probes directly, and the temperature error is suppressed. Moreover,the temperature can be measured accurately without being influenced from changes in the environment.

Use at cupola of probe - END -