Continuous tempersture measuring probes | Protectuve tube(MZ Tube)| Expendable thermocouple |

Japan Thermotec co.,Ltd. that contributes to manufacturing such as steel making,cast metal foundry, and conner base alloys making.

Site Search >>

We provide various type protective tubes for thermocouple according to the material and the size in order to use it to measure the temperature under the severe environment such as molten metal and heat treatment furnace. Moreover,we take orders design and manufacturing a temperature sensor which assembles thermocouple, flange, and terminal box. If you consult us, we will design for the sensor and write a written estimate.

※The custom-made product is published on the actual results and the usage pages.

We will select the best material according to the temperature and atmosphere, etc.

|

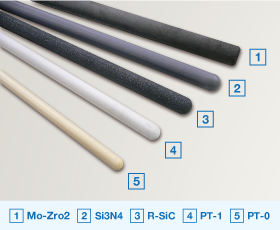

Mo-ZrO2、Mo-Al2O3-ZrO2、Mo-Al2O3protective tube |

|---|---|

| Metallic protective tube (Stainless steel, Inconel, and Cantal and others) | |

| Alumina protective tube (PT-0, PT-1) | |

| Silicon carbide system protective tube (R-SiC, Si-SiC, N-Sic, and pressureless sintering SiC) | |

| Silicon nitride system protection tube (Si3N4 and Sialon) |

We take orders design and manufacturing a temperature sensor which assembles thermocouple, flange, and terminal box. If you consult us, we will design for the sensor and write a written estimate.

※The custom-made product is published on the actual results and the usage pages.

|

The Cermet (Mo-ZrO2) balancedly inosculates metallic molybdenum of high melting point (melting point of Mo is 2,625℃) and zirconia of high-corrosion resistance (melting point of ZrO2 is 2,677℃). It has an excellent characteristic as a protective tube for the continuous temperature measuring probe, because it is sustainable in the temperature of molten metal(steel or cast iron) or in high temperature environment by its excellent heat resistance and corrosion resistance. |

|---|

| Profile |

|---|

|

|

|

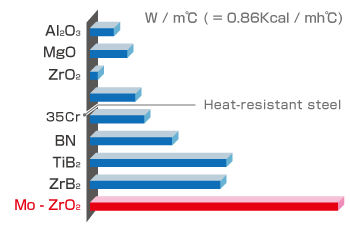

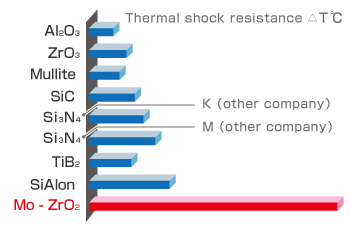

| Graph compared material property of Mo and others | |

|---|---|

| Thermal conductivity | Thermal shock |

|

|

| Responsivity for the temperature variation is excellent because of high thermal conductivity of Mo. | Because Mo is a metal, the cermet can endure high thermal shock. Therefore it can be used without preheating. |

Physical property value

Cermet protective tube

| Items | Characteristic value | |

|---|---|---|

| Apparent porosity (%) | 0.15 | |

| Coefficient of water absorption (%) | 0.04 | |

| Apparent specific gravity | 8.34 | |

| Compressive strength (MPa) | at R.T. | 1043 |

| Bending strength | at R.T. at 1,400℃ |

342 192 |

| Thermal conductivity (w / m / k) | at R.T. at 1,400℃ |

41.1 68.1 |

| Coefficient of thermal expansion ( x 10-8 / ℃) | at 1,000℃ / 1Hr at 1,500℃ / 1Hr |

7.15 7.63 |